Unravelling the Mystery: Digital Twin Technology?

Hello there! If you’ve stumbled upon this post, chances are you’re interested in the intriguing world of digital twin technology. Grab yourself a coffee (or a cup of tea if that’s your preference) and allow me to guide you through the fascinating maze of digital twins.

Understanding the Concept: Digital Twin Explained

Definition and Basic Explanation: What is a Digital Twin?

We’ve all dreamt at some point of having a double to do our chores while we have fun. Well, on a non-human level, this is somewhat possible with the advent of the Digital Twin. In simple terms, a Digital Twin is a virtual replica of a physical object or system that replicates its behavior in real-time.

Imagine you have a physical object – it might be your car, a building, a power plant, or even an entire city. Now, imagine you could create an exact digital copy of this object – a twin if you will, living and evolving in the digital realm. This copy, or ‘twin,’ can simulate and predict all possible scenarios and behaviors of its physical counterpart. Isn’t it fascinating?

Simply put, a digital twin is a virtual model of a process, product, or service. This pairing of the virtual and physical world allows the analysis of data and monitoring of systems to prevent problems before they even start, plan for the future, and create new opportunities. Digital twins might seem like a concept from a sci-fi movie but it’s very much a reality in today’s tech-driven era.

Origin and Evolution: Looking at the History of Digital Twin Technology

While the Digital Twin might seem like a buzzword from the past decade, its roots trace back to NASA’s Apollo missions. They employed rudimentary forms of Digital Twins for problem-solving and failure prediction in their space crafts.

Fast forward to today, and digital twins, armed with the power of IoT (Internet of Things), cloud computing, and AI, have reached a whole new level of capabilities. They’ve swiftly moved from being rare, expensive systems owned by a handful of tech-savvy companies, to being an integral part of various industries, including manufacturing, construction, healthcare, and urban planning.

Components and Working of a Digital Twin:

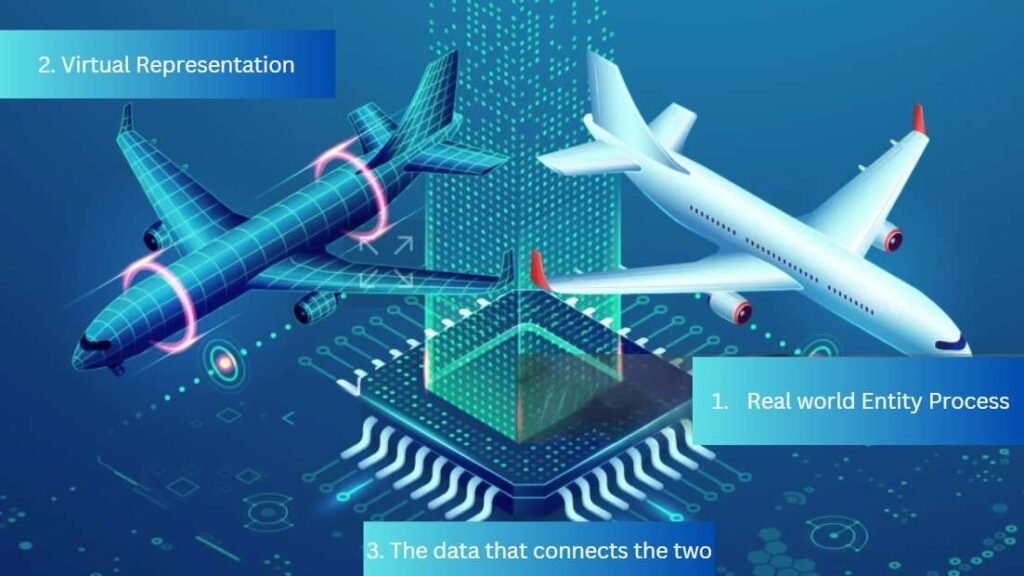

Now lets understand the three key components of Digital twins: There are three components of a digital twin: 1. Real world entity process 2. Virtual representation and 3. The data that connects the two.

Table of Contents

Toggle

Real World Entity/Process: This is the physical object or system that the digital twin is created to represent. It can be anything from a single piece of equipment like a turbine to an entire factory or even a complex natural ecosystem. The key characteristic is that it exists in the real world and its behavior can be observed and measured.

Virtual Representation: This is the digital replica of the real-world entity. It can be a 3D model, a set of mathematical equations, or any other type of digital representation that captures the essential characteristics and behaviors of the real-world counterpart. The goal is to create a virtual model that is as accurate and detailed as possible to mirror the real world object.

Data that Connects the Two: This is the bridge between the physical and digital worlds. It encompasses all the data that flows back and forth between the real-world entity and its digital representation. This includes data from sensors, actuators, monitoring systems, and other sources that provide real-time information about the physical object’s state and behavior. The data is then used to update the virtual model and keep it as close to the real world as possible.

A Digital Twin isn’t some magical entity. It’s a combination of key components like sensors (for data collection), data analytics (for understanding the data), and a virtual platform (a 3D model, for instance, where the data is visualized).

Simulation and Prediction: How a Digital Twin Replicates Real-World Objects/Systems

Simply put, a Digital Twin relies on sensor data from the physical object and then uses sophisticated algorithms to mimic the object’s behavior. This near-instant data transfer allows a Digital Twin to be used as a real-time mirror image.

Interface & Interaction: How Users Engage with Digital Twins

Generally, users interact with a Digital Twin on a dashboard where sensor data is visualized. This dashboard can show anything from real-time performance metrics to potential failure points, giving users an array of insights.

Digital Twin’s Different Forms:

Time to dig a bit deeper. Did you know that there are different types of digital twins? It all depends on what you wish to simulate or predict. Let’s take a sneak peek into a couple of them.

Design Twins

Imagine you’re an architect designing a skyscraper. With Design Twins, you can create a highly-detailed 3D model of the building, simulate different environmental conditions, assess the building’s durability, and even predict maintenance needs. It’s like playing a super-advanced version of the popular game ‘SimCity,’ except the results have real-world implications.

Performance Twins

On the other hand, suppose you’re an engineer at a manufacturing plant. You’d use Performance Twins to track the functioning of the machines in real-time, identify bottlenecks, and predict potential breakdowns before they occur. It’s almost like having a crystal ball that forewarns you about the future.

Twins” are for monitoring runtime performance. Some businesses have even moved towards more specialized twins, like ‘Process Twin’, which tracks processes in real-time!

Digital Twin in Practice: Varied Industry Use Cases

Digital Twin in manufacturing Sector: Enhancing Efficiency and Predicting Failures

Manufacturers have adopted Digital Twin technology to enhance operational efficiency and reduce unexpected machine downtimes. For instance, they’ve used Digital Twins to monitor equipment health and predict potential failures even before they happen!

Healthcare Industry: Personalized Treatment and Preventive Healthcare

The healthcare industry is also digitally replicating human organs or even entire physiological systems! The benefits range from personalizing treatment plans based on patient-specific Digital Twins to predicting health problems before they become serious.

Smart Cities and Infrastructure: Planning, Implementing, and Monitoring at Scale

Imagine if city planners could foresee the impacts of a new flyover or a housing project! Through Digital Twin technology, they can simulate traffic patterns, population growth, and environmental impacts before launching large-scale projects.

Transformative Impact: How Digital Twin Can Level Up Your Business

Digital twin in Predictive Maintenance: Mitigating Risks and Reducing Downtime

From weekend barbeques to business infrastructure, everyone hates a last-minute crisis. Digital Twin Technology can predict such crises in business, thus helping you schedule maintenance work at a convenient time rather than facing unexpected downtimes.

Digital Twin in Innovation and Optimization: How Digital Twin Aids in Research and Development

Do you always get an idea right on the first try? That’s a rarity! And that’s where Digital Twins can help. They let researchers test their ideas in a virtual environment, thus fast-tracking innovation while reducing development costs.

The Financial Angle: Cost Savings and Return on Investment

With predictive maintenance minimizing downtime and research optimization reducing production costs, Digital Twins can positively impact any business’s bottom line. This is not including the added benefits of improved customer satisfaction due to the efficient functioning of your services.

Looking Forward: Future Trends and Challenges

The Future of Digital twins: Upcoming Trends in Digital Twin Technology

From entire soccer games to complex ecosystems, almost everything could have their Digital Twin. Who knows, one day, you might have your Digital Twin attending those long office meetings on your behalf!

Digital twin Technology are rapidly evolving from futuristic concepts to practical tools transforming industries worldwide. As technology advances and adoption increases, exciting trends are emerging, shaping the future of this transformative technology. Here are some of the most noteworthy:

Hyper-realism and Increased Fidelity:

Digital twins are becoming increasingly sophisticated, mirroring their physical counterparts with near-perfect accuracy. This hyper-realism is achieved through advancements in:

Sensor technology: More powerful and diverse sensors capture a wider range of data, providing a more comprehensive picture of the physical asset.

Modeling and simulation tools: Advanced physics engines and machine learning algorithms create more accurate simulations of real-world behavior.

3D modeling and visualization: High-fidelity 3D models enable detailed visualization of the digital twin, facilitating deeper analysis and understanding.

AI-powered Insights and Automation:

Artificial intelligence (AI) is playing a crucial role in unlocking the full potential of digital twins. AI-powered features like:

Predictive maintenance: Analyze data from the digital twin to anticipate equipment failures and schedule maintenance proactively, minimizing downtime and costs.

Self-optimization: AI algorithms can autonomously adjust settings and parameters in the physical asset based on real-time data from the digital twin, optimizing performance and efficiency.

Automated decision-making: AI can analyze data and suggest optimal courses of action in complex situations, empowering faster and more informed decision-making.

Democratization and Accessibility:

Digital twin technology is becoming more accessible and affordable, thanks to:

Cloud-based platforms: Cloud computing provides scalable and cost-effective infrastructure for hosting and managing digital twins, making them accessible to even small and medium-sized businesses.

Digital Twins as a Service (DTaaS): DTaaS models offer pre-built and customizable digital twin solutions, eliminating the need for extensive in-house development and expertise.

Open-source tools and standards: The emergence of open-source tools and standards is making it easier for developers to create and share digital twin solutions, fostering innovation and collaboration.

Interconnected and Collaborative Digital Twins:

The future holds the potential for interconnected and collaborative digital twins. Imagine:

City-scale digital twins: Multiple digital twins of buildings, infrastructure, and transportation systems can be integrated to create a comprehensive digital model of an entire city, enabling better planning, resource management, and emergency response.

Supply chain digital twins: Connecting digital twins across different stages of a supply chain can optimize logistics, track goods in real-time, and improve transparency and efficiency.

Federated learning: Digital twins can share and learn from each other’s data, leading to faster development of more accurate and intelligent models.

Ethical Considerations and Responsible Development:

As digital twins become more sophisticated and integrated into critical systems, ethical considerations arise. These include:

Data privacy and security: Ensuring robust data protection measures to prevent unauthorized access and misuse of sensitive data.

Algorithmic bias: Mitigating potential bias in AI algorithms used in digital twins to ensure fair and equitable outcomes.

Transparency and explainability: Making the decision-making processes of AI-powered digital twins transparent and understandable to stakeholders.

By addressing these ethical concerns and promoting responsible development, digital twins can unlock their full potential to benefit individuals, businesses, and society as a whole.

The future of digital twins is bright, filled with possibilities for enhanced efficiency, optimized processes, and transformative insights. As these trends continue to evolve, we can expect digital twins to play an increasingly vital role in shaping the world of tomorrow.

Potential Hurdles: Overcoming Data Privacy and Security Concerns

With great advancements come great responsibilities. As Digital Twin technology becomes more pervasive, businesses have to remain vigilant about data privacy and security concerns.

Adapting to Change: How Businesses Can Adopt and Benefit From Digital Twin

Businesses keen on implementing Digital Twin technology should start small. Gradually, as understanding and capabilities improve, they can scale their Digital Twin efforts to cover more extensive areas of their operations.

Summary

In conclusion, while digital twin technology might appear complicated at first glance, they’re essentially just a powerful tool to enhance our understanding, decision-making, and forecasting abilities. As a way to bridge the physical and the digital world, they are playing an increasingly important role in a wide range of industries.

So next time you hear the term ‘digital twin,’ remember – it’s not as complex as it sounds. It’s just your everyday object, living a parallel life in the digital world. Not exactly ‘The Matrix’, is it? But almost as cool.

You now possess a basic understanding of digital twin technology. Overall, digital twins power digital transformation by bridging the gap between physical assets and digital systems, promoting data-driven decision-making, and enabling continuous improvement. They offer a transformative leap, not just in specific processes, but in the entire way businesses operate and adapt in the digital age.

As digital transformation and technology advance, expect even more exciting developments in digital twin functionality and integration, further blurring the lines between the physical and digital realms.

Always remember, a little bit of knowledge can open a digital floodgate of possibilities—and there’s no better time to start exploring these opportunities than now. Happy exploring!

Manufacturing: Monitor equipment performance in real-time, predict failures for proactive maintenance, optimize production processes, and virtually test new product designs.

Energy: Simulate energy grids for efficient power distribution, track renewable energy sources, and optimize energy consumption in buildings.

Healthcare: Create personalized patient models for diagnosis, treatment planning, and surgical simulations.

Retail: Design and optimize store layouts, personalize customer experiences, and predict product demand based on real-time data.

Supply Chain: Track shipments in real-time, monitor warehouse conditions, and optimize logistics for faster delivery.

Identify core assets or processes: Choose specific assets or processes that would benefit most from a digital twin.

Gather data: Collect real-time data from sensors, IoT devices, and other sources.

Build the digital twin: Create a virtual model of the chosen asset or process using the collected data.

Integrate with existing systems: Connect the digital twin to your existing enterprise platforms for data exchange and analysis.

Refine and update: Continuously monitor and update the digital twin with new data to ensure its accuracy.

Boeing: Uses digital twins to design and build jet engines with improved efficiency and performance.

Siemens: Offers digital twin solutions for power generation, wind turbines, and other industrial applications.

GE Aviation: Utilizes digital twins to predict and prevent engine failures in aircraft.

UPS: Employs digital twins to optimize shipping routes and delivery times.

Frito-Lay: Leverages digital twins to monitor equipment performance and improve manufacturing efficiency.

Data security: Sensitive data from the physical asset and its digital twin needs robust security measures to prevent cyberattacks.

Cost and complexity: Developing and maintaining a sophisticated digital twin can be expensive and require specialized expertise.

Data overload: Processing and analyzing large volumes of data from the digital twin can be challenging.

Overreliance on technology: Digital twins should complement human expertise, not replace it.

Limited scope: A digital twin only accurately reflects the aspects of the physical asset it’s designed for.

The timeline for seeing results varies depending on the complexity of the digital twin and the specific application.

Short-term benefits: Operational improvements and cost savings can be seen within months of implementation.

Long-term benefits: Enhanced product design, predictive maintenance, and optimized processes can take longer to materialize, typically between 1-3 years.

Remember, successful digital twin implementations require careful planning, collaboration, and ongoing maintenance to yield the desired results.